Technology

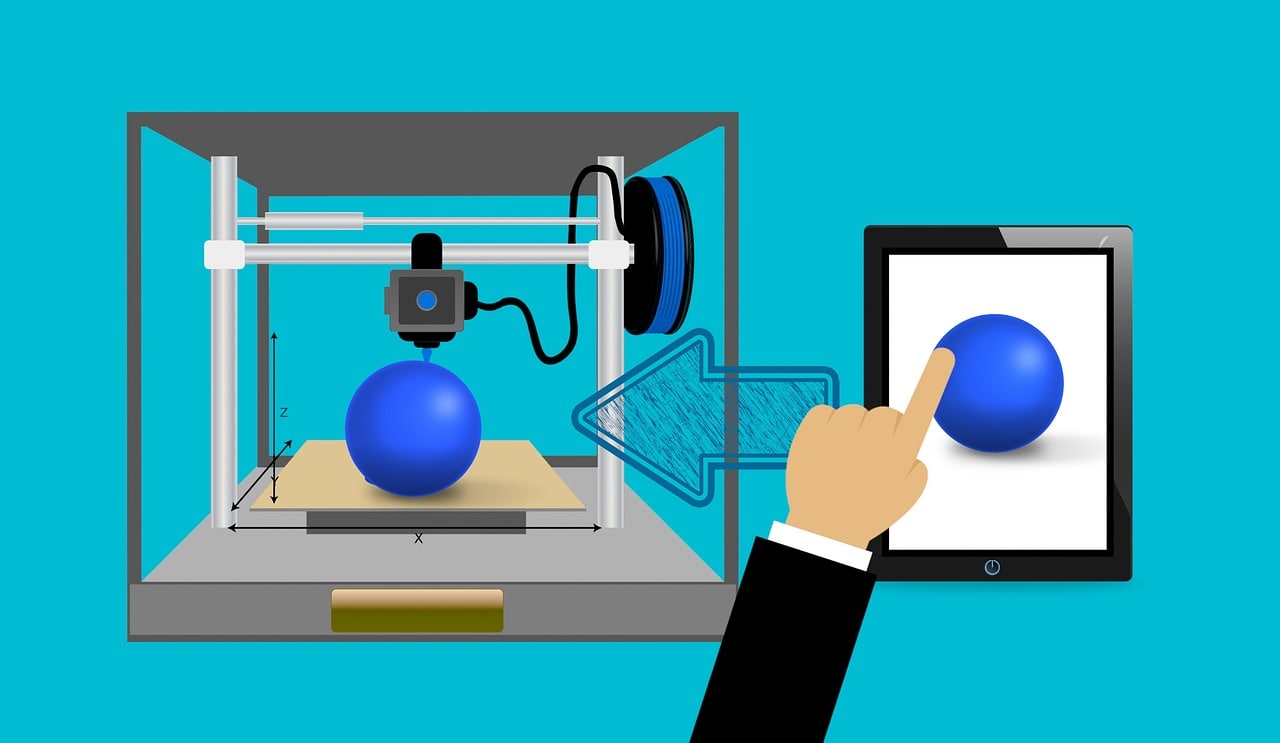

Use of 3D Printing in Injection Molding

Use of 3D Printing in Injection moulding, Injection moulding is a 3d printing manufacturing process for 3d objects by injecting molten material into a mould

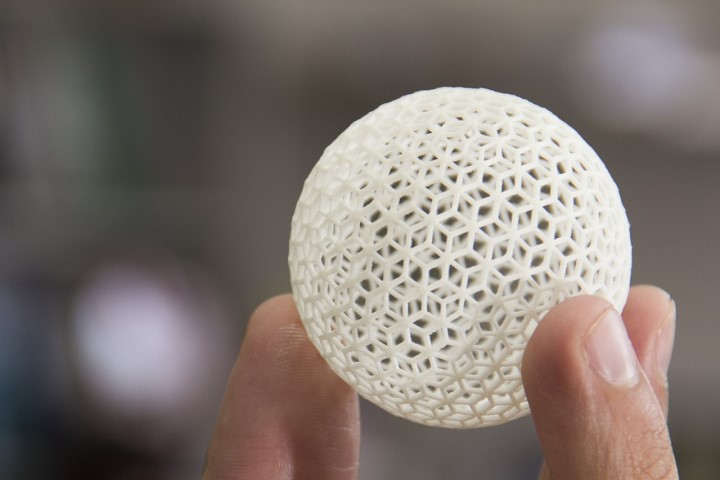

The recent years have seen 3D printing to become extremely useful in manufacturing. This is most specifically true in plastic injection moulding. The companies make use of a 3D printer to create a specific part from a model, concept plastic art and drawing. It can take 20 minutes to 48 hours depending on the complexity and size. In most cases, you are able to get hold of a finished replica of your part in just about a matter of a few hours. Hire reliable cheap injection moulding services.

One of the major developments to have taken place today in the field of 3D printing is its ability to print a plastic injection mould. Today the 3D molding technology need not have narrow part tolerances needed to make a plastic injection mold which can withstand extremely high volume. Once the part tolerances are solved, the mold making will surely become a viable option that will have a number of benefits.

Are 3D printing and injection moulding complementary of each other?

3D printing and injection moulding are not competing for technologies as much as they are complementary. They can be used theoretically used for manufacturing and can also be used technically for rapid prototype generation. The trend for the processes of additive manufacturing is growing with the rising time. The most serious kind of manufacturing is performed with injection mouldingequipment. In most cases, a 3D printer is an effective tool for the development of the rapid prototype.

Injection moulding is one of the most common methods for mass producing parts of plastic. This is specifically ideal for producing large numbers of identical parts having tight tolerances. The past had witnessed 3D designing in the manufacturing and design process to create and also verify prototypes which would be injection molded later.

Injection moulding is a highly demanding application for 3D printed material and the molds need to withstand the forces at a high temperature while retaining the dimensional accuracy. The 3D printing in injection molds are suited for the following:

- » Fast turnaround times

- » Mold designs wherein iterations and changes are probably

- » Low production quality applications

- » Parts which are relatively small

Why use 3D printing?

It is crucial to consider the number of parts the mold is going to use. The materials provide extremely good wear resistance to repeated injection, closing and opening of the mold along with the temperature gradients. These were exposed to during the process of injection moulding.

For low-run molding, the wear resistance is not the most critical factor. Certain technologies of 3D printing such as SLA and Material Jetting are capable of producing parts of high accuracy having an excellent surface finish. This is further coupled with the modern temperature that is resistant to 3D printing materials. 3D printed molds allow quick verification of mold design and mitigate the financial risk of investing in an expensive metal mold.

Conclusion

High stiffness, high level of detail and high-temperature resistance is all that is required to create injection mold from 3D printing. Thus, the use of 3D printing in injection moulding is highly important. Make use of the best cheap injection moulding services.

Helpful Resources:

1. 16 Best (free) AMP – (Accelerated Mobile Pages) WordPress Plugins in [2019]

2. 16 Best Free SEO WordPress plugins for your Blogs & websites in [2019]

3. Riverdale Cast List For The TV Show Riverdale

4. Top 25 Best SolarMovie Alternatives in [2019]

5. Top 5 Best Web Development Frameworks For Popular Programming Languages in [2019]

Hardware

Ways Paper Cutting Machine Is Used To Craft Perfection And Reduce Complexity

Here Are Seven Reasons Why Paper Cutting Machines Are Used To Craft Perfection And Reduce Complexity: Ways Paper Cutting Machine Is Used To Craft Perfection And Reduce Complexity.

Are you someone who appreciates detailed paper crafts’ beauty but lacks the patience to create them? What if we told you that with a simple machine, you could craft creations with great precision and complexity in no time? Enter The paper cutting machine! This incredible device has revolutionized paper crafting, enabling makers of cards, scrapbooks, confetti shapes, and more to achieve perfection quickly.

We’ll explore some fantastic ways these machines can be used to make custom works of art. So get ready as we show you how this tremendous tool gives crafters access to new project possibilities!

Here Are Seven Reasons Why Paper Cutting Machines Is Used To Craft Perfection And Reduce Complexity:

Table of Contents

1. Creating intricate designs for greeting cards and invitations

Nothing beats the accuracy and precision of a paper-cutting machine when creating intricate designs for greeting cards and invitations. Gone are the days of relying solely on time-consuming hand-cutting techniques that often resulted in less-than-perfect designs. With a paper-cutting machine, crafting perfection is achievable with ease and efficiency.

These machines allow for intricate designs, from delicate floral patterns to detailed geometric shapes. By reducing the complexity and frustration that often comes with hand-cutting, paper-cutting devices provide a seamless and enjoyable way to create beautiful cards and invitations that are sure to impress.

2. Decorating scrapbook pages with intricate and precise shapes

Decorating your scrapbook pages can be a fun and rewarding way to preserve your memories, but it can also be time-consuming and complex. Fortunately, paper-cutting machines are available to help you easily create intricate and precise shapes.

These machines use computer-aided technology to cut complex designs and patterns, reducing the complexity of the crafting process and ensuring that every profile is perfect and consistent. Whether you are a seasoned scrapbooker or just starting, a paper-cutting machine can be a valuable tool to help you create stunning works of art.

3. Crafting intricate 3D paper models

Crafting intricate 3D paper models is a form of art that demands precision and creativity. This technique can work wonders in today’s world, where we strive for perfection and simplicity. But what are the benefits of laser cutting in the textile industry? With the ability to create complex structures and shapes, it is no wonder that artists and architects have used this technique for ages to present their ideas and plans. The process involves cutting, folding, and gluing pieces of paper to create a three-dimensional model.

This technique allows you to visualize an object in a highly realistic, tangible way you could not achieve with a drawing. Furthermore, creating 3D paper models can be therapeutic, allowing us to focus our minds on a task and escape from the stress of our everyday lives. So, if you want to try something new and exciting, give it a shot – the results might surprise you!

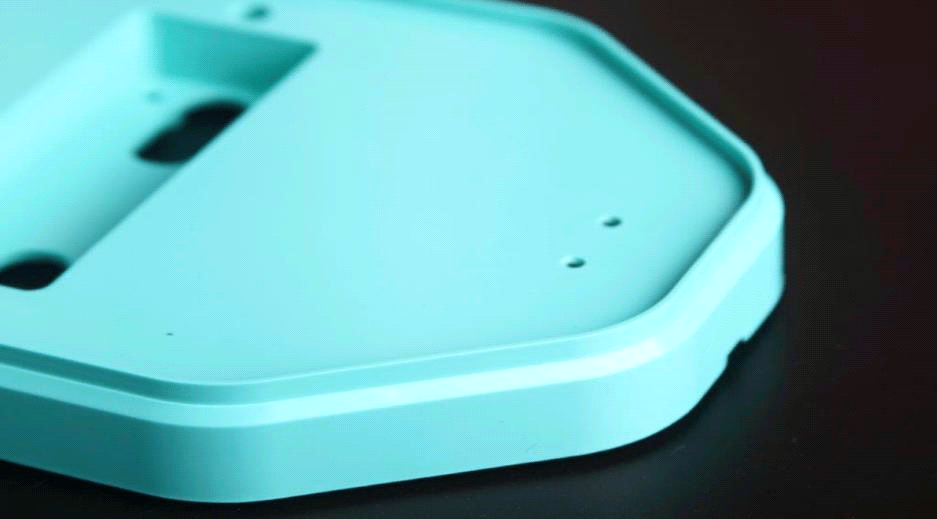

4. Producing uniform and precise paper shapes for packaging

The world of packaging can be complex, with various sizes and forms required to fit different products. However, with the help of paper-cutting machines, producing uniform and precise paper shapes has become easier than ever before. These machines use advanced technology to create intricate and complex designs, ensuring that every piece is perfectly crafted.

From small businesses producing their packaging to large manufacturers, paper-cutting machines have revolutionized the industry, reducing complexity and improving overall efficiency. Whether making boxes, bags, or other packaging, these machines offer a solution for businesses looking to streamline their production process and achieve consistent results.

5. Designing precise paper stencils for painting and drawing

Precision is key in the art of painting and drawing. Every stroke counts, which is why many artists have turned to paper-cutting machines to help them easily craft masterpieces. With a paper-cutting machine, designing precise paper stencils has become a breeze.

These stencils can be customized to any shape or size, allowing artists to create intricate designs that would have been nearly impossible to achieve by hand. Paper cutting eliminates the need for measuring and cutting by hand, reducing complexity and streamlining the artistic process. Whether working on a large-scale painting or a small sketch, a paper-cutting machine is a tool for artists who demand perfection in their craft.

6. Creating custom paper artwork for home décor

Creating custom paper artwork for home décor has never been easier, thanks to today’s innovative paper-cutting machines. Crafting perfection in paper cutting has never been simpler, allowing artists of all abilities to create stunning, intricate designs easily. These cutting machines have various features that reduce complexity, such as automatic positioning and intuitive software.

With the ability to cut precise shapes and sizes, these machines allow limitless creative possibilities, making them a must-have tool for any paper artist or enthusiast. Whether adding a personal touch to your home décor or creating unique gifts for loved ones, a paper-cutting machine is a perfect way to bring your creative vision to life.

7. Crafting unique and intricate designs for paper-quilling projects

Creating paper quilling designs can be both a fun and challenging task. With intricate and unique patterns, you can make beautiful pieces of art that impress you. But don’t let the complexity of paper quilling scare you away! Utilizing this art form can lead to exquisite and near-perfect designs. You must know why laser cutting is the best solution for the industry.

By allowing yourself to be creative with shapes, colors, and designs, you can make paper quilling more than just a hobby – it can become an exciting and rewarding hobby. The beauty of paper quilling is that it is an accessible art form for almost anyone willing to learn. So why not take a chance, pick up some paper, and start quilling? The possibilities are endless!

Conclusion

To sum it up, paper-cutting machines have revolutionized how people craft perfect projects with ease and reduced complexity. These machines’ design capabilities are remarkable, allowing for even more intricate details and intricate layouts that were previously impossible.

They can also save a tremendous amount of time since they eliminate the tedium of manually adjusting each paper pattern or designing complex shapes. With these advanced features, it’s no wonder why so many choose to invest in a paper-cutting machine for an incredible array of projects. Crafting perfection has never been easier!

-

Instagram2 years ago

Instagram2 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram2 years ago

Instagram2 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business4 years ago

Business4 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram3 years ago

Instagram3 years agoInstagram Followers And Likes – Online Social Media Platform